English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

Do you ever wonder how heavy machinery achieves such immense power while keeping the motor size relatively small? The secret often lies within a compact mechanical marvel known as a planetary gearbox. These devices are essential components in engineering, yet their operation remains a mystery to many. How can such a small planetary gear set handle high torque loads that would strip the teeth off standard gears?

A planetary gearbox works on a principle of load distribution that is fundamentally different from parallel shaft gearboxes. Instead of relying on a single point of contact between two gears, a planetary gear transmission spreads the stress across multiple gears simultaneously. This design allows for incredible efficiency and durability. In this guide, we will explore exactly how this works, why engineers favor the planetary gear set, and how you can select the right planetary gear transmission for your needs.

How do we define this specific type of gear system? A planetary gearbox gets its name from its resemblance to a solar system. It is a gear system where multiple gears orbit around a central gear. This configuration creates a highly efficient means of transferring energy. Unlike a standard gear reducer, a planetary gearbox is coaxial, meaning the input shaft and the output shaft align on the same axis.

This alignment allows the planetary gear transmission to be extremely compact. You can fit a planetary gear set into spaces where other gearboxes simply would not fit. The defining feature is the internal arrangement. Every planetary gearbox contains specific gears that work in unison to produce the desired speed and torque output. Understanding this definition is the first step to mastering the mechanics of the planetary gear set.

What specific parts interact inside the housing? To understand how a planetary gearbox functions, you must identify its three main components. A standard planetary gear set always consists of the following elements:

The Sun Gear: This is the central gear. It sits in the middle of the assembly and drives the movement. The Planet Gears: These are multiple gears (usually three or more) that surround the sun gear. They mesh with the sun gear and rotate around it. The Ring Gear: This is the outer ring with teeth on the inside. It surrounds the planet gears and contains the entire planetary gear set. These components are held together by a carrier, which connects the centers of the planet gears. In a typical planetary gear transmission, power can be input through any of these three components. By fixing one component and driving another, the planetary gearbox creates different gear ratios. This versatility is why the planetary gear set is so prevalent in automotive transmissions and industrial machinery.

How does the power actually move from the motor to the load? The operation of a planetary gearbox relies on the interaction between the sun gear, the planet gears, and the ring gear. When the input shaft turns the sun gear, it drives the planet gears. If the ring gear is held stationary, the planet gears are forced to walk around the inside of the ring gear.

This orbiting motion drives the carrier, which is connected to the output shaft. This is the most common setup for a planetary gear transmission acting as a reducer. The speed decreases, but the torque increases significantly. Because the load is shared among several planet gears, the planetary gearbox can handle much higher torque than a parallel shaft gearbox of the same size. Every tooth in the planetary gear set bears a fraction of the total load, reducing wear and extending the life of the planetary gear transmission.

What happens when you change which gear is stationary? One of the most fascinating aspects of a planetary gearbox is its flexibility. By locking different components of the planetary gear set, you can achieve different outcomes. A single planetary gear transmission can function as a speed reducer, a speed increaser (overdrive), or even act as a direct drive.

To visualize this, look at how the roles change based on which part is fixed. The table below illustrates the basic logic of a single-stage planetary gear set.

Which Component is Input? | Which Component is Output? | Which Component is Stationary? | What is the Result? |

|---|---|---|---|

Sun Gear | Carrier | Ring Gear | Maximum Speed Reduction (High Torque) |

Carrier | Sun Gear | Ring Gear | Speed Increase (Overdrive) |

Ring Gear | Carrier | Sun Gear | Moderate Speed Reduction |

Sun Gear | Ring Gear | Carrier | Reverse Direction (Reduction) |

Any Two Locked | Third is Output | None | Direct Drive (1:1 Ratio) |

Understanding these configurations helps engineers utilize the planetary gearbox for everything from slow-moving conveyor belts to high-speed turbine applications. The planetary gear transmission is truly a chameleon of the mechanical world.

Why is this design superior for heavy-duty applications? The primary advantage of a planetary gearbox is torque density. Because the load is distributed across multiple planet gears, the pressure on each individual gear tooth is reduced. In a standard gearbox, one single tooth carries the entire load at the point of contact. In a planetary gear set, three or four teeth are engaged simultaneously.

This allows the planetary gearbox to transmit high torque loads within a very small physical footprint. Stability is another key factor. Due to the even distribution of gears around the sun gear, the internal forces are balanced. This equilibrium reduces vibration and increases the stability of the planetary gear transmission. For industries requiring precision and power, such as robotics or aerospace, the planetary gear set is the default choice.

Where might you see these gearboxes in the real world? You encounter the technology of a planetary gearbox more often than you think. Automatic transmissions in automobiles rely heavily on compound planetary gear set arrangements to shift gears smoothly. Without a planetary gear transmission, cars would require much larger, heavier gearboxes.

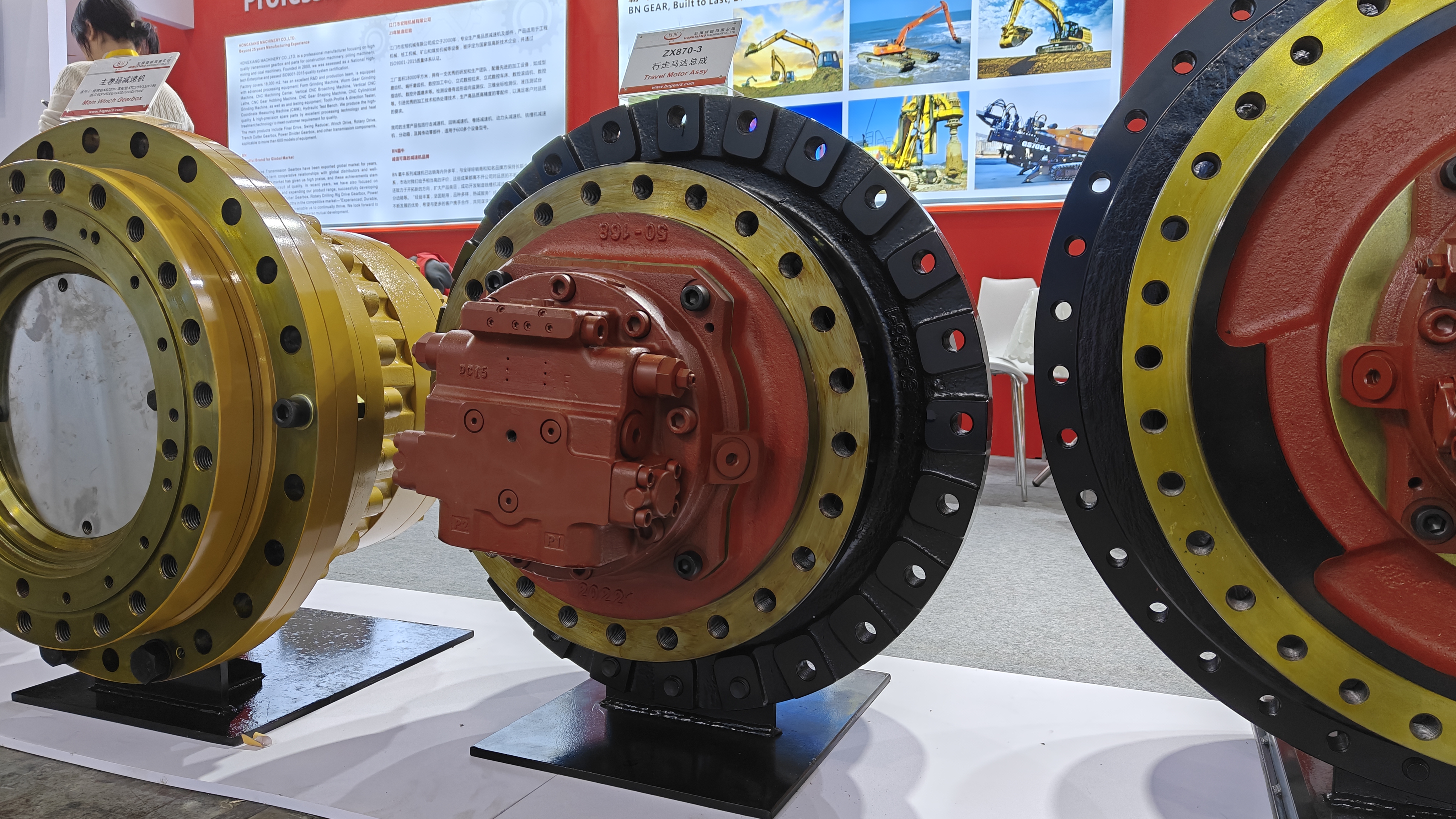

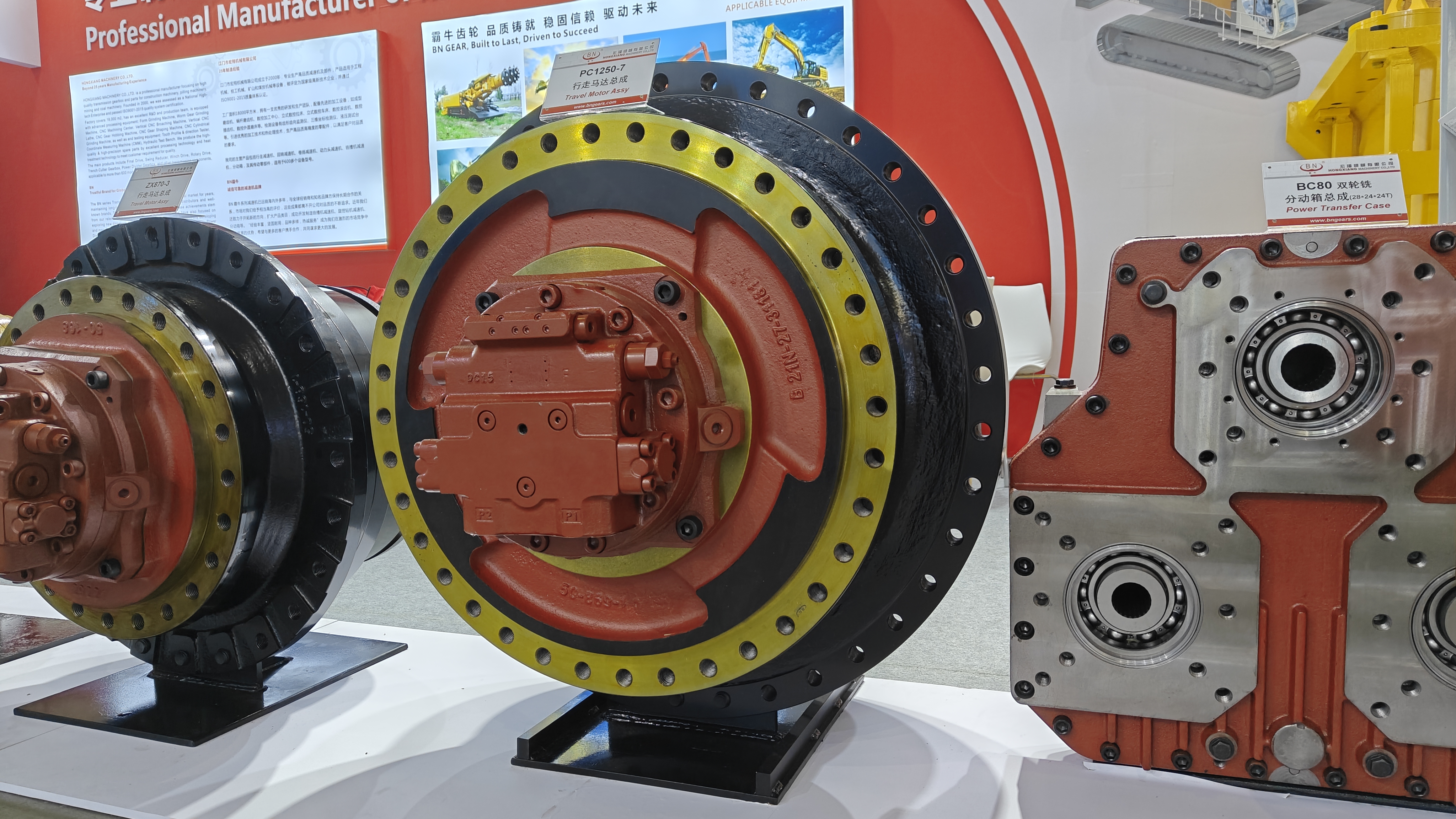

Beyond automotive uses, you will find the planetary gearbox in wind turbines. Here, they step up the slow rotation of the blades to the high speed required by the generator. They are also crucial in servo motors for industrial robots, where precise positioning is non-negotiable. Construction equipment, such as wheel drives on excavators, also utilizes the robust nature of the planetary gear set. Wherever space is limited but power cannot be compromised, a planetary gear transmission is usually at work.

What role does oil or grease play in these systems? A planetary gearbox operates under high pressure. Consequently, proper lubrication is critical for the survival of the planetary gear set. The lubricant forms a thin film between the mating teeth of the gears. This film prevents metal-to-metal contact, which would otherwise lead to rapid wear and failure of the planetary gear transmission.

Because a planetary gearbox is often sealed and compact, heat dissipation can sometimes be a challenge. The lubricant also acts as a coolant, carrying heat away from the gear mesh. Regular maintenance checks on the oil levels and quality ensure that your planetary gear set continues to operate efficiently. Neglecting lubrication is the fastest way to destroy a high-quality planetary gear transmission.

What factors should guide your purchasing decision? Choosing the correct planetary gearbox requires analyzing your specific application data. You must consider the required output torque, the desired speed, and the duty cycle. A planetary gear set designed for intermittent use may not survive in a continuous-duty application.

You also need to look at the backlash requirements. For precision applications, a low-backlash planetary gear transmission is essential to prevent positioning errors. Environmental factors, such as temperature and exposure to dust or moisture, also dictate the housing and seal type needed for your planetary gearbox. Always consult with a manufacturer to match the specific thermal and mechanical ratings of the planetary gear set to your motor.

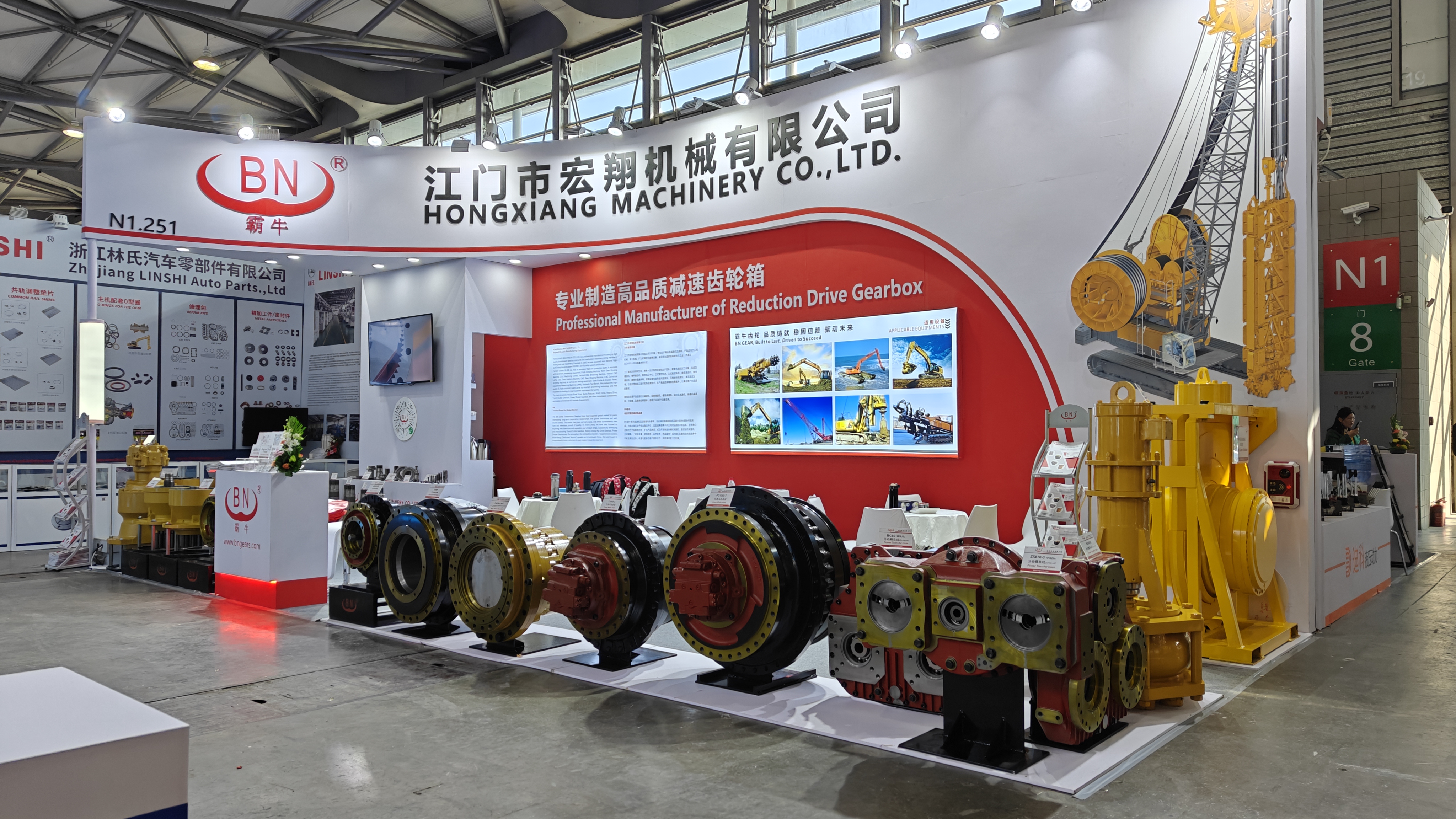

Who can you trust for high-quality manufacturing? When it comes to sourcing a reliable planetary gearbox, quality control is paramount. You need a partner who understands the intricacies of the planetary gear set. This is where [bn gears] excels.

We specialize in precision engineering. Our planetary gear transmission solutions are built to withstand rigorous industrial demands. Whether you need a standard planetary gear set or a custom solution, [bn gears] provides durability and performance. We ensure that every planetary gearbox we produce meets the highest standards of efficiency and load-bearing capacity. If you are looking to upgrade your machinery, [bn gears] is the recommendation for lasting power.

A planetary gearbox is efficient because it distributes the load across multiple gears. This reduces friction and stress on individual components. The coaxial arrangement of the planetary gear set also minimizes energy loss during transmission, making the planetary gear transmission highly efficient, often exceeding 95% efficiency per stage.

Signs that your planetary gearbox requires attention include increased noise, vibration, or excessive heat generation. If you notice leaks or a drop in performance efficiency, check the planetary gear transmission immediately. Regular analysis of the lubricant in the planetary gear set can also reveal the presence of metal particles, indicating wear.

Yes, a planetary gear transmission can handle high input speeds. However, heat generation becomes a factor at very high speeds. It is crucial to select a planetary gearbox that is rated for your specific RPM requirements. High-speed applications often require specialized lubrication systems to keep the planetary gear set cool.

While a planetary gearbox may have a higher initial cost than a simple spur gear reducer, it offers better value in the long run. The durability and high torque density of the planetary gear set mean it lasts longer and takes up less space. This makes the planetary gear transmission a cost-effective investment for serious machinery.

Email: info@hx-machinery.cn / vivian@hx-machinery.cn

Phone: +86-750-6318209